Corrosion Coupons and Test Specimens

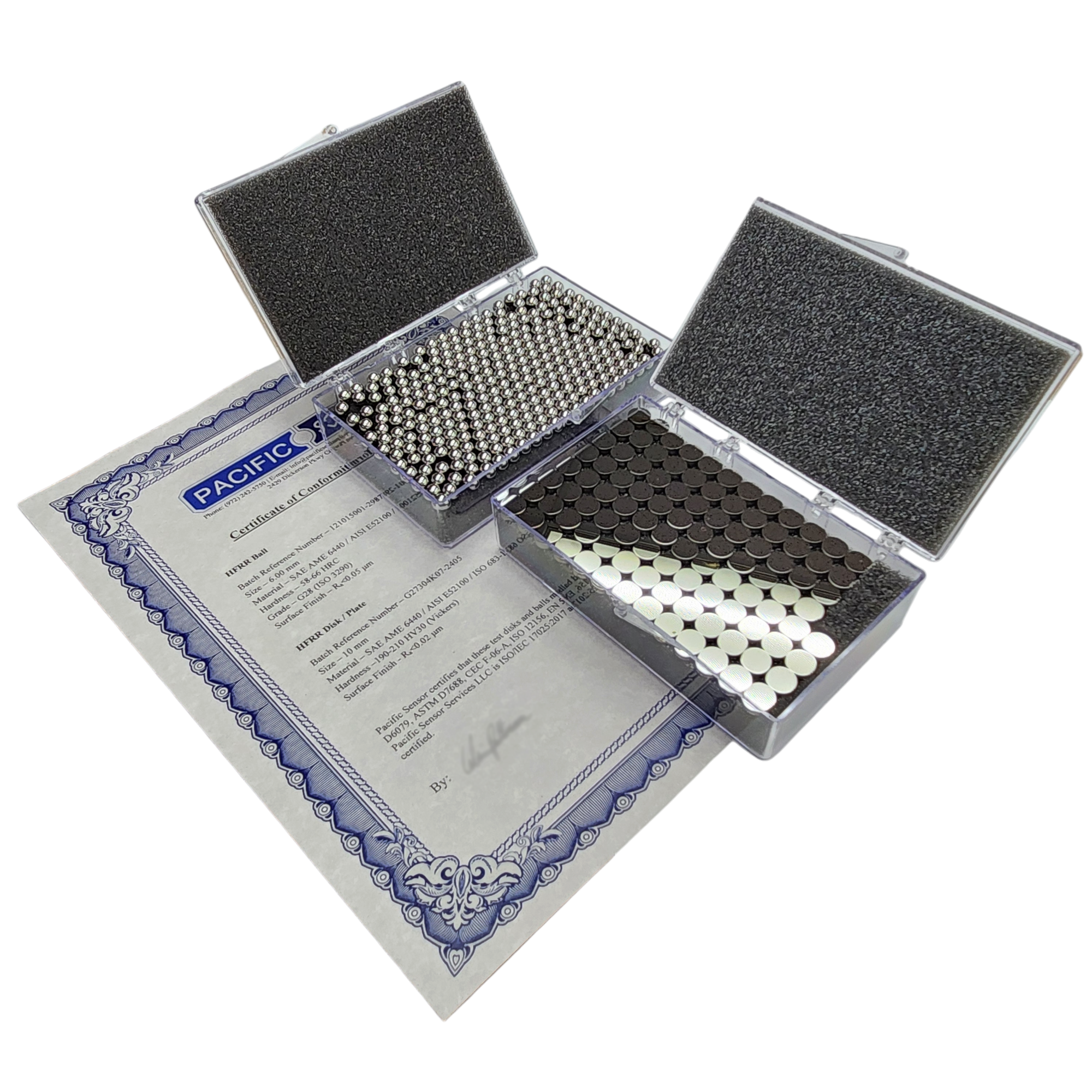

Est. 1993, Pacific Sensor is one of the world’s largest manufacturers of corrosion coupons and test specimens, supplying hundreds of thousands of products annually to customers across the globe. Our products include corrosion coupons, coupon racks, linear polarization (LPR) probes, ASTM D6079 HFRR specimens, and a variety of custom test specimens. All corrosion coupons are weighed and analyzed in our ISO 17025-accredited laboratory following ASTM G1 and NACE SP0775 standards. We have proudly served the oil and gas and water treatment industries for over 30 years, delivering high-quality corrosion coupons and test specimens that meet stringent industry standards and support critical applications worldwide.

Featured Products

ASTM D3241 JFTOT Heater Tubes